In a rapidly developing world which is heavily dependent on metals and mining, it is imperative that mining equipment and vehicles receive topnotch consideration and services. Earthmovers, one of the significant mining automobiles, need to be maintained carefully and regularly. Mining activity is subjected to heavy loads, rough terrain, and long hours of operation. The environment of its working is rough and the weather can get extreme. All these factors affect the performance and life of the vehicle. Since mining is the backbone of infrastructural development, we need to ensure that no such hurdle befalls it.

Tyre is the very base of a healthy vehicle, and we need to keep in mind that earthmover tyres are no different. There are several manufacturers who produce earthmover tyres, offering varying levels of specifications. Mining operations demand earthmover tyres have a high load-carrying capacity, reduced wear, resistance to cuts, cooler running, lower contact pressure, and many more characteristics.

In this article, we will discuss some of the key reasons for Earthmover tyre damages.

Causes of Damage

Earthmover tyres can be subjected to damage if proper measures are not taken against it. Some of the critical causes of damage can be:

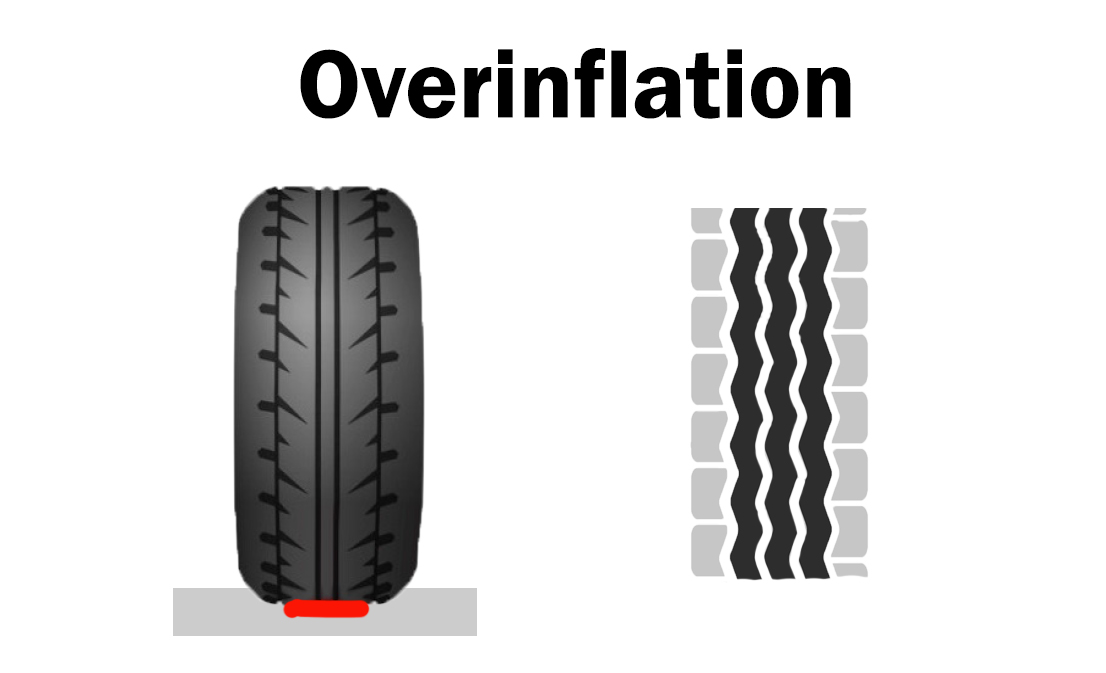

Under or over-inflation: This will severely affect the performance of the tyre as air pressure gives the tyre the capability to bear the load correctly. Underinflation can lead to fatigue and heat build-up within the tyres due to excessive flexing of the sidewall. This can cause structural deterioration and damages in the tyres such as separation failures. Overinflation on the other hand leads to premature wear of the tread, reduced resistance to impacts and cuts, and uneven wear.

Overloading: A hazard to any and all types of vehicles, overloading will risk the performance of the tyre. It can lead to abnormal temperatures rises, increased flexing, and weakening of the tyre structure which may lead to premature scrapping of the tyre even if the tread still shows very little sign of wear.

Excessive speeding: This will also cause an increase in the internal temperature of the tyre, causing its components to overheat, resulting in irreversible damage to the tire’s structure.

Mechanical Forces: damages can be caused or aggravated by:

-

- Hammering connected with regular impact on the tread blocks, traveling over very hard, smooth surfaces on high speed.

- Centrifugal forces connected with the curvature of the bends and cornering speed.

- Impact on poorly maintained surfaces (badly graded, presence of stones, holes, ruts, etc.) haul roads, face area, and the dumping site.

Therefore it is imperative for the mine maintenance engineers and technicians to keep a check and regularly monitor the above parameters to ensure Earthmover tyres are worn out delivering the desired life and NOT THROWN OUT.